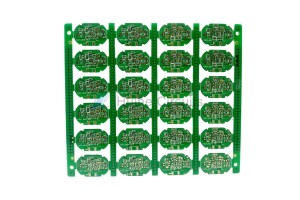

10 Layer ENIG FR4 Ta Cikin PCB

Ta hanyar In Pad PCB

A cikin ƙirar PCB, rami-rami shine tazarar sarari tare da ƙaramin ramin da aka ɗora a cikin allon da'ira da aka buga don haɗa layin dogo na tagulla akan kowane Layer na allo.Akwai wani nau'in rami mai suna microhole, wanda kawai yana da ramin makaho da ke iya gani a saman daya samanPCB multilayer mai girmako wani rami da ba a iya gani a cikin ko wane saman.Gabatarwa da faffadan aikace-aikace na sassan fil masu girma, da kuma buƙatar ƙaramin PCBS, sun kawo sabbin ƙalubale.Don haka, mafi kyawun maganin wannan ƙalubalen shine amfani da sabuwar fasahar kera PCB amma shahararriyar fasahar kera da ake kira "Via in Pad".

A cikin ƙirar PCB na yanzu, ana buƙatar amfani da sauri ta hanyar a cikin kushin saboda raguwar tazarar sawun sawun sawun sawun sawun sawun sawun sawun sawun sawun sawun da kuma ƙara girman sifofin PCB.Mafi mahimmanci, yana ba da damar siginar sigina a cikin ƴan wurare na shimfidar PCB gwargwadon yiwuwa kuma, a mafi yawan lokuta, har ma yana guje wa ketare kewayen da na'urar ta mamaye.

Pads masu wucewa suna da amfani sosai a cikin ƙira mai sauri yayin da suke rage tsayin waƙa don haka inductance.Zai fi kyau ka bincika don ganin ko masana'anta na PCB na da isassun kayan aiki don kera allo, saboda wannan na iya kashe kuɗi da yawa.Koyaya, idan ba za ku iya sanya ta cikin gasket ba, sanya kai tsaye kuma amfani da fiye da ɗaya don rage inductance.

Bugu da ƙari, ana iya amfani da kushin wucewa a yanayin rashin isasshen sarari, kamar a cikin ƙirar micro-BGA, wanda ba zai iya amfani da hanyar gargajiya ta fan-out.Babu shakka cewa lahani na ta hanyar rami a cikin faifan waldawa ƙananan ƙananan ne, saboda aikace-aikacen a cikin faifan walda, tasirin farashin yana da girma.Rikicin tsarin masana'antu da farashin kayan masarufi sune manyan abubuwa biyu waɗanda ke shafar farashin samar da filler.Na farko, Via in Pad wani ƙarin mataki ne a cikin tsarin kera PCB.Koyaya, yayin da adadin yadudduka ke raguwa, haka ma ƙarin farashin da ke alaƙa da Via a cikin fasahar Pad.

Abvantbuwan amfãni na Ta hanyar PCB

Via in pad PCBs suna da fa'idodi da yawa.Na farko, yana sauƙaƙa ƙãra ɗimbin yawa, amfani da fakitin tazara mafi kyau, da rage inductance.Menene ƙari, yayin aiwatar da hanyar ta cikin kushin, ana sanya ta kai tsaye ƙasa da madaidaicin lambar sadarwa na na'urar, wanda zai iya cimma mafi girma da yawa da kuma mafi girman kwatance.Don haka yana iya adana babban adadin PCB sarari tare da ta cikin kushin don mai tsara PCB.

Idan aka kwatanta da makafi ta vias da binne vias, via a pad yana da fa'idodi masu zuwa:

Dace dalla-dalla nesa BGA;

Inganta yawan PCB, ajiye sarari;

Ƙara zafi mai zafi;

An ba da lebur da coplanar tare da kayan haɗi;

Domin babu alamar kashin kashin kare, inductance yana ƙasa;

Ƙara ƙarfin ƙarfin lantarki na tashar tashar tashar;

Via In Pad Application Don SMD

1. Toshe ramin da guduro kuma farantin shi da tagulla

Mai jituwa tare da ƙananan BGA VIA a cikin Pad;Na farko, tsarin ya haɗa da cika ramuka tare da kayan aiki ko kayan aiki, sa'an nan kuma sanya ramukan a saman don samar da wuri mai laushi don shimfidar walda.

Ana amfani da ramin fasikanci a ƙirar kushin don ɗora abubuwan da aka gyara akan ramin wucewa ko don tsawaita mahaɗin solder zuwa haɗin ramin wucewa.

2. Microholes da ramukan suna plated akan kushin

Microholes sune ramukan tushen IPC tare da diamita na ƙasa da 0.15mm.Yana iya zama rami ta hanyar rami (wanda ke da alaƙa da yanayin yanayin), duk da haka, yawanci ana ɗaukar microhole azaman rami makaho tsakanin yadudduka biyu;Yawancin microholes ana hako su da lasers, amma wasu masana'antun PCB kuma suna hakowa tare da raƙuman injiniyoyi, waɗanda suke a hankali amma yanke da kyau da tsabta;A Microvia Cooper Fill tsari ne wani electrochemical jijiya tsari ga multilayer PCB masana'antu tafiyar matakai, kuma aka sani da Capped VIas;Kodayake tsarin yana da rikitarwa, ana iya sanya shi zuwa HDI PCBS wanda yawancin masana'antun PCB zasu cika da tagulla microporous.

3. Toshe rami tare da juriya na walda

Yana da kyauta kuma mai jituwa tare da manyan pads SMD mai siyarwa;Daidaitaccen tsarin waldawar juriya na LPI ba zai iya samar da cika ta cikin rami ba tare da haɗarin jan ƙarfe maras tushe a cikin ganga ramin.Gabaɗaya, ana iya amfani da shi bayan bugu na allo na biyu ta hanyar adana juriya na UV ko zafin warkewar epoxy a cikin ramuka don toshe su;Ana kiran shi ta hanyar toshewa.Toshe ramuka shine toshe ramuka tare da kayan juriya don hana zubar iska yayin gwada farantin, ko don hana gajerun abubuwa na kusa da saman farantin.

-300x225.png)