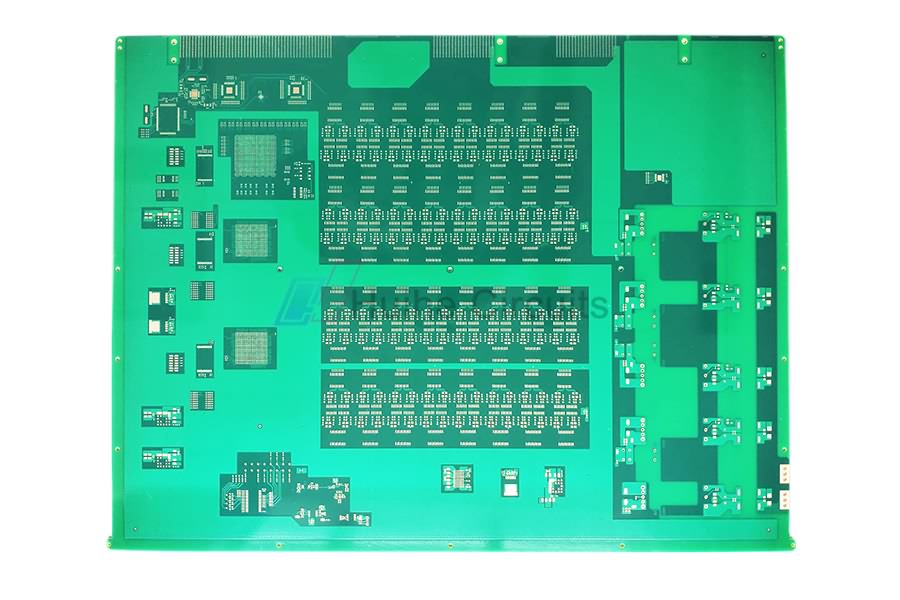

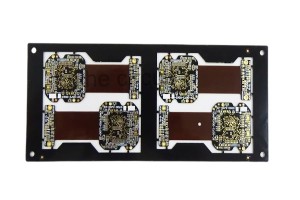

16 Layer ENIG Latsa Fit Hole PCB

Game da Via-In-Pad PCB

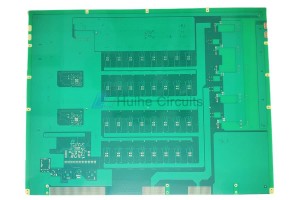

Via-In-Pad PCBs gabaɗaya makafi ne, waɗanda galibi ana amfani da su don haɗa Layer na ciki ko na biyu na HDI PCB tare da Layer na waje, don haɓaka aikin lantarki da amincin samfuran lantarki, gajarta siginar. watsa waya, rage inductive reactance da capacitive reactance na watsa layin, kazalika da ciki da kuma waje electromagnetic tsangwama.

Ana amfani da shi don gudanarwa.Babban matsalar ramukan toshe a cikin masana'antar PCB shine zubar mai daga ramukan toshe, wanda za'a iya cewa cuta ce mai ci gaba a masana'antar.Yana da matukar tasiri ga ingancin samarwa, lokacin bayarwa da ingancin PCB.A halin yanzu, yawancin PCBs masu girman gaske suna da irin wannan ƙira.Don haka, masana'antar PCB na buƙatar gaggawa don magance matsalar zubar mai daga ramukan toshe

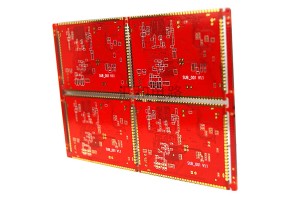

Babban Dalilan Fitar Man Fetur Daga Via In Pad Plug Hole

Tazara tsakanin toshe rami da kushin: a cikin ainihin PCB anti-welding tsarin samar, sai dai farantin ramin yana da sauki tserewa.Sauran ramin filogi da tazarar taga bai wuce 0.1mm 4mil) da ramin toshewa da tagar anti-sayar da tangential, farantin tsaka-tsaki kuma yana da sauƙin wanzuwa bayan magance zubar mai;

PCB kauri da budewa: kauri farantin karfe da budewa suna da alaƙa da inganci tare da digiri da rabon fitar da mai;

Zane-zanen fina-finai mai kama da juna: lokacin da Via-In-Pad PCB ko ƙaramin ramin tazara ya haɗu da kushin, fim ɗin layi ɗaya zai ƙira gabaɗaya wurin watsa haske a matsayin taga (don fallasa tawada a cikin rami) "don guje wa tawada a cikin. rami yana shiga cikin kushin yayin haɓakawa, amma ƙirar isar da hasken ya yi ƙanƙanta don cimma tasirin fallasa, kuma wurin watsa hasken yana da girma sosai don haifar da kashewa cikin sauƙi.Yana samar da koren mai akan PAD.

Yanayin warkewa: saboda ƙirar madaidaicin madaidaicin Via-In-Pad PCB zuwa fim ɗin ya kamata ya zama ƙasa da rami, ɓangaren tawada a cikin rami ya fi madaidaicin madaidaicin lokacin da ba a fallasa shi zuwa haske.Tawada ba magani ba ne mai ɗaukar hoto, haɓakawa bayan buƙatun gabaɗaya don juyar da fallasa ko UV sau ɗaya, don warkar da tawada a nan.An kafa wani Layer na fim ɗin warkarwa a saman ramin don hana haɓakar zafi na tawada a cikin ramin bayan an warke.Bayan warkewa, tsawon lokacin sashin ƙananan zafin jiki, da ƙananan zafin jiki na ƙananan zafin jiki, ƙananan rabo da digiri na fitar da man fetur;

Toshe tawada: daban-daban masana'antun na tawada dabara daban-daban ingancin ingancin su ma za su sami wani bambanci.

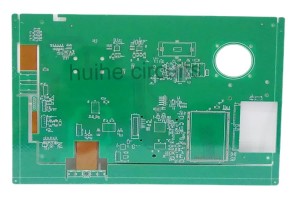

Nunin Kayan aiki

PCB Layin Plating Na atomatik

Layin PCB PTH

PCB LDI

PCB CCD Exposure Machine

Nunin Masana'antu

PCB Manufacturing Tushen

Admin Receptionist

Dakin Taro