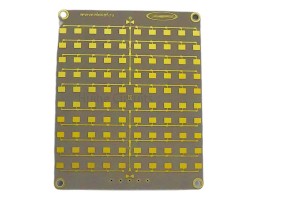

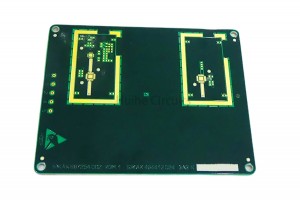

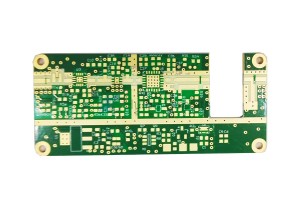

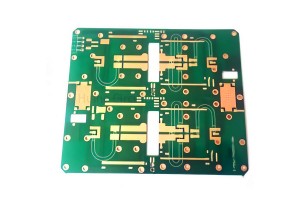

4 Layer ENIG RO4003+AD255 Mixed Lamination PCB

RO4003C Rogers Babban Mitar PCB Materials

Ana iya cire kayan RO4003C tare da goga na nailan na al'ada.Ba a buƙatar kulawa ta musamman kafin yin amfani da tagulla ba tare da wutar lantarki ba.Dole ne a bi da farantin ta amfani da tsarin epoxy/gilasi na al'ada.Gabaɗaya, ba lallai ba ne a cire rijiyar burtsatse saboda babban tsarin resin TG (280°C+[536°F]) baya canza launi cikin sauƙi yayin aikin hakowa.Idan aikin hakowa mai tsanani ne ya haifar da tabon, za'a iya cire resin ta amfani da daidaitaccen zagayowar jini na CF4/O2 ko ta hanyar tsarin permanganate na alkaline dual.

RO4003C kayan saman na iya zama na inji da/ko an shirya shi ta hanyar sinadarai don kariyar haske.Ana ba da shawarar yin amfani da daidaitattun masu ruwa-ruwa ko masu ɗaukar ruwa mai ruwa.Ana iya amfani da kowane goge tagulla da aka samu na kasuwanci.Duk abubuwan da za a iya tacewa ko masu iya siyar da hoto da aka saba amfani da su don epoxy/glass laminates suna manne da saman ro4003C.Tsaftace injin injina na filayen dielectric da aka fallasa kafin a yi amfani da abin rufe fuska na walda da keɓance “masu rijista” da keɓaɓɓun saman dole ne su guje wa mannewa mafi kyau.

Bukatun dafa abinci na kayan ro4000 daidai suke da na epoxy/gilasi.Gabaɗaya, kayan aikin da ba su dafa epoxy/glass ba ya buƙatar dafa faranti ro4003.Don shigar da gilashin epoxy/gasa a matsayin wani ɓangare na tsari na al'ada, muna ba da shawarar dafa abinci a 300°F, 250°f (121°c-149°C) na 1 zuwa 2 hours.Ro4003C ba ya ƙunshi mai hana wuta.Ana iya fahimtar cewa farantin da aka haɗa a cikin naúrar infrared (IR) ko aiki a cikin ƙananan saurin watsawa zai iya kaiwa yanayin zafi fiye da 700 ° F (371 ° C);Ro4003C na iya fara konewa a waɗannan yanayin zafi.Tsarukan da har yanzu suke amfani da na'urorin reflux infrared ko wasu kayan aiki waɗanda zasu iya kaiwa waɗannan yanayin zafi ya kamata su ɗauki matakan da suka dace don tabbatar da cewa babu haɗari.

Ana iya adana manyan laminates masu tsayi har abada a cikin zafin jiki (55-85 ° F, 13-30 ° C), zafi.A cikin zafin jiki, kayan aikin dielectric ba su da ƙarfi a babban zafi.Koyaya, suturar ƙarfe irin su jan ƙarfe na iya yin oxidize lokacin da aka fallasa su zuwa babban zafi.Daidaitaccen sharewar PCBS na iya cire lalata cikin sauƙi daga kayan da aka adana da kyau.

A RO4003C abu za a iya machined ta amfani da kayan aikin yawanci amfani da epoxy / gilashin da wuya karfe yanayi.Dole ne a cire murfin jan karfe daga tashar jagora don hana lalata.

Rogers RO4350B/RO4003C Material Siga

| Kayayyaki | Saukewa: RO4003C | Saukewa: RO4350B | Hanyar | Naúrar | Sharadi | Hanyar Gwaji |

| Dk (ε) | 3.38± 0.05 | 3.48± 0.05 | - | 10GHz/23 ℃ | IPC.TM.6502.5.5.5Gwajin layin microstrip manne | |

| Dk (ε) | 3.55 | 3.66 | Z | - | 8 zuwa 40 GHz | Hanyar tsawon lokaci daban-daban |

| Dalilin hasara (tan δ) | 0.00270.0021 | 0.00370.0031 | - | 10GHz/23 ℃2.5GHz/23 ℃ | IPC.TM.6502.5.5.5 | |

| Yawan zafin jiki nadielectric akai-akai | +40 | +50 | Z | ppm / ℃ | 50 ℃ zuwa 150 ℃ | IPC.TM.6502.5.5.5 |

| Juriya girma | 1.7X100 | 1.2X1010 | MΩ.cm | COND A | IPC.TM.6502.5.17.1 | |

| Juriya na Surface | 4.2X100 | 5.7x109 | MΩ | 0.51mm(0.0200) | IPC.TM.6502.5.17.1 | |

| Juriyar Lantarki | 31.2(780) | 31.2(780) | Z | KV/mm(V/mil) | RT | IPC.TM.6502.5.6.2 |

| Modulus Tensile | 19650 (2850)19450 (2821) | 16767 (2432)14153 (2053) | XY | MPa(kpsi) | RT | Saukewa: ASTM D638 |

| Ƙarfin Ƙarfi | 139 (20.2)100 (14.5) | 203 (29.5)130 (18.9) | XY | MPa(kpsi) | Saukewa: ASTM D638 | |

| Karfin Lankwasawa | 276(40) | 255(37) | MPa(kpsi) | IPC.TM.6502.4.4 | ||

| Girman Kwanciyar hankali | 0.3 | 0.5 | X, Y | mm/m(mils/inch) | Bayan etchingE2/150 ℃ | IPC.TM.6502.4.39A |

| CTE | 111446 | 101232 | XYZ | ppm / ℃ | 55 zuwa 288 ℃ | IPC.TM.6502.4.41 |

| Tg | :280 | :280 | Farashin DSC | A | IPC.TM.6502.4.24 | |

| Td | 425 | 390 | ℃ TGA | Saukewa: ASTM D3850 | ||

| Thermal Conductivity | 0.71 | 0.69 | W/m/K | 80 ℃ | Saukewa: ASTM C518 | |

| Yawan Sha Danshi | 0.06 | 0.06 | % | 0.060" samfurori an nutsar da su a cikin ruwa a 50 ° C na 48 hours | Saukewa: ASTM D570 | |

| Yawan yawa | 1.79 | 1.86 | gm/cm3 | 23 ℃ | Saukewa: ASTM D792 | |

| Ƙarfin Kwasfa | 1.05(6.0) | 0.88(5.0) | N/mm(plikasi) | 1 oz ku.EDC bayan bleaching tin | IPC.TM.6502.4.8 | |

| Jinkirin harshen wuta | N/A | V0 | Farashin UL94 | |||

| Lf Jiyya Dace | Ee | Ee |

Aikace-aikace Na RO4003C Babban Mitar PCB

Kayayyakin sadarwar wayar hannu

Power Splitter, coupler, duplexer, tace da sauran m na'urorin

Amplifier Ƙarfin Ƙarfin Ƙarfafa, Ƙarfin Ƙarfafa Ƙwararru, da sauransu

Na'urar rigakafin karo na mota, tsarin tauraron dan adam, tsarin rediyo da sauran fannoni

Nunin Kayan aiki

PCB Layin Plating Na atomatik

Layin PCB PTH

PCB LDI