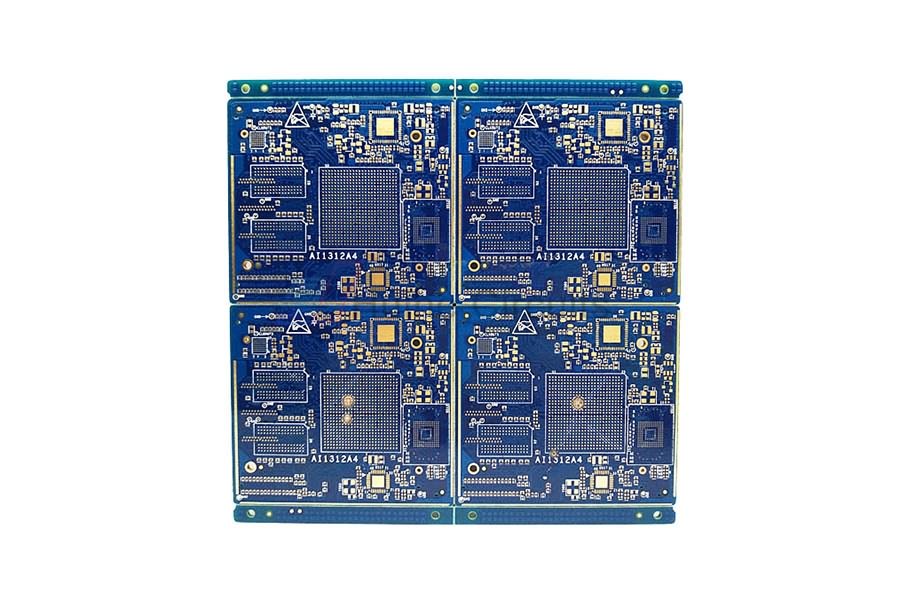

4 Layer ENIG Impedance Control PCB Copper Copper

Tsare-tsare Don Ƙirƙirar Injiniya Na PCB mai nauyi na Copper

Tare da ci gaban fasahar lantarki, girman PCB yana ƙara ƙarami, yawa yana ƙara ƙaruwa, kuma matakan PCB suna ƙaruwa, sabili da haka, yana buƙatar PCB akan tsarin haɗin kai, ikon tsangwama, tsari da buƙatun masana'anta shine mafi girma. kuma mafi girma, kamar yadda abun ciki na aikin injiniya zane sosai, yafi ga nauyi tagulla PCB masana'anta, sana'a workability da amincin samfurin injiniya zane, shi bukatar ya zama saba da zane misali da kuma saduwa da bukatun na samar da tsari, yin da tsara. samfurin lafiya.

1. Inganta daidaituwa da daidaito na shimfidar jan karfe na ciki Layer

(1) Saboda superposition sakamako na ciki Layer solder kushin da iyakance guduro kwarara, da nauyi jan karfe PCB zai zama thicker a cikin yankin tare da high saura jan karfe kudi fiye da a cikin yankin tare da low saura tagulla kudi bayan lamination, sakamakon rashin daidaito. kauri daga cikin farantin da kuma shafi m faci da taro.

(2) Saboda PCB mai nauyi na jan karfe yana da kauri, CTE na jan karfe ya bambanta sosai da na ma'auni, kuma bambancin nakasa yana da girma bayan matsa lamba da zafi.Tsarin ciki na rarraba tagulla ba daidai ba ne, kuma warpage na samfurin yana da sauƙin faruwa.

Matsalolin da ke sama suna buƙatar haɓakawa a cikin ƙirar samfurin, a cikin yanayin rashin tasiri da aiki da aikin samfurin, ɗakin ciki na yankin da ba shi da tagulla kamar yadda zai yiwu.A zane na jan karfe batu da jan karfe block, ko canza babban jan karfe surface zuwa jan karfe batu kwanciya, inganta kwatance, sa ta yawa uniform, mai kyau daidaito, sa overall layout na hukumar m da kyau.

2. Inganta ƙimar ragowar jan ƙarfe na Layer na ciki

Tare da karuwar kauri na jan karfe, rata na layin ya fi zurfi.A cikin yanayin saura na jan karfe iri ɗaya, adadin cikawar resin yana buƙatar haɓaka, don haka ya zama dole a yi amfani da zanen gado da yawa da aka warke don saduwa da cikar manne.Lokacin da resin ya ragu, yana da sauƙi don haifar da rashin lamination na manne da daidaituwa na kauri na farantin.

Matsakaicin ragowar jan ƙarfe yana buƙatar babban adadin guduro don cika, kuma motsin guduro yana iyakance.A karkashin aikin matsa lamba, kauri na dielectric Layer tsakanin yankin takardar jan karfe, yankin layi da yanki na yanki yana da babban bambanci (kauri na dielectric Layer tsakanin layin shine mafi ƙanƙanci), wanda yake da sauƙin kai ga gazawar HI-POT.

Saboda haka, da jan karfe saura kudi ya kamata a inganta kamar yadda zai yiwu a cikin zane na nauyi jan karfe PCB injiniya, don haka kamar yadda a rage bukatar manne cika, rage AMINCI hadarin manne cika rashin gamsuwa da bakin ciki matsakaici Layer.Misali, wuraren jan ƙarfe da ƙirar tagulla an shimfiɗa su a cikin yankin kyauta na tagulla.

3. Ƙara faɗin layi da tazarar layi

Don PCBs na jan karfe mai nauyi, haɓaka tazarar faɗin layin ba wai kawai yana taimakawa rage wahalar sarrafa etching ba, har ma yana da babban ci gaba a cikin ciko manne.Gilashin fiber ɗin da ke cike da ƙaramin tazara ya ragu, kuma gilashin fiber ɗin da ke cike da babban tazara ya fi.Babban tazara na iya rage matsa lamba na cika manne mai tsabta.

4. Haɓaka ƙirar kushin Layer na ciki

Don PCB na jan karfe mai nauyi, saboda kauri na jan karfe yana da kauri, tare da babban matsayi na yadudduka, jan ƙarfe yana cikin babban kauri, lokacin hakowa, juzu'in kayan aikin rawar soja a cikin jirgi na dogon lokaci yana da sauƙi don samar da lalacewa. , sa'an nan kuma rinjayar ingancin bangon rami, kuma ya kara rinjayar amincin samfurin.Sabili da haka, a cikin matakan ƙira, ya kamata a tsara ƙirar ciki na pad ɗin da ba a yi aiki ba kamar yadda zai yiwu, kuma ba a ba da shawarar fiye da 4 yadudduka ba.

Idan zane ya ba da izini, ya kamata a tsara ginshiƙan rufin ciki kamar yadda zai yiwu.Ƙananan pads za su haifar da damuwa mafi girma a cikin aikin hakowa, kuma saurin tafiyar da zafi yana da sauri a cikin tsarin sarrafawa, wanda ke da sauƙi don haifar da fashewar Angle na jan karfe a cikin pads.Ƙara nisa tsakanin kushin mai zaman kansa na Layer na ciki da bangon rami gwargwadon izinin ƙira.Wannan na iya ƙara ingantaccen tazara tsakanin ramin tagulla da kushin Layer na ciki, da rage matsalolin da ke haifar da ingancin bangon rami, irin su micro-short, gazawar CAF da sauransu.